Truck air conditioner troubleshooting involves checking for common issues such as refrigerant leaks and electrical problems. A malfunctioning air conditioner can cause discomfort during long drives and hinder driver productivity.

We will explore various troubleshooting steps to help identify and resolve any issues with your truck’s air conditioning system, ensuring a comfortable and reliable driving experience.

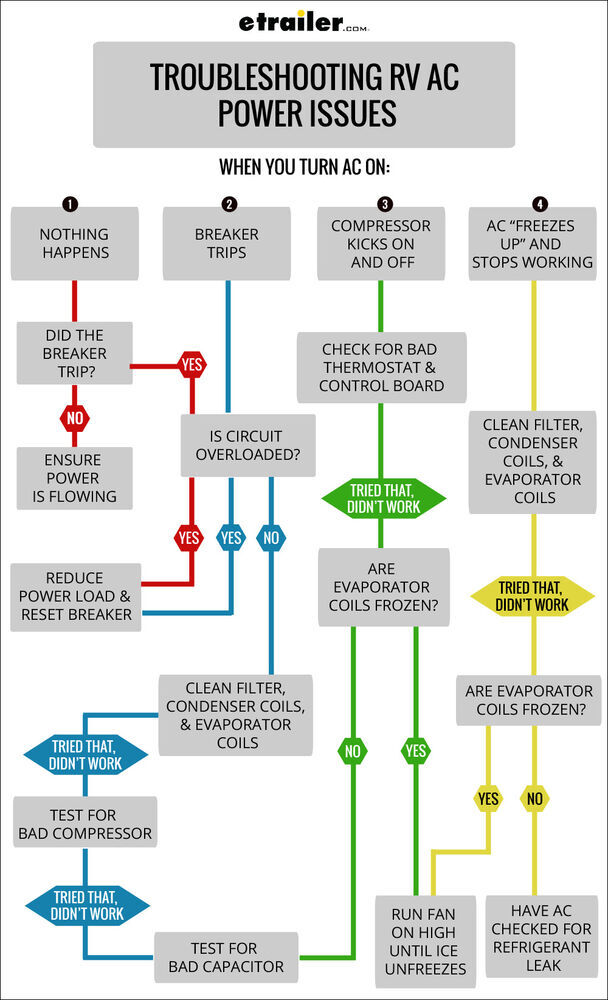

Credit: www.etrailer.com

Common Issues With Truck Air Conditioners

Truck air conditioners play a crucial role in maintaining driver comfort during long journeys. However, like any mechanical system, they can experience issues that need troubleshooting. In this section, we will explore the common issues that truck air conditioners often encounter and the steps you can take to address them effectively.

Refrigerant Leaks

One of the most common problems with truck air conditioners is refrigerant leaks. Refrigerant is responsible for cooling the air in the system, and a leak can greatly affect its performance. If you notice that your truck’s air conditioner is blowing warm air or takes longer than usual to cool down, it may have a refrigerant leak. In such instances, it is crucial to get the leak repaired promptly.

There are a few reasons why refrigerant leaks occur, such as worn-out hoses, loose fittings, or damaged seals. To pinpoint the exact location of the leak, it is best to take your truck to a qualified technician. They will have the necessary tools and expertise to identify and fix the leak.

Electrical Problems

Another common issue that truck air conditioners may face is electrical problems. If your air conditioner fails to turn on, has intermittent cooling, or experiences sudden shutdowns, the culprit may be an electrical malfunction. Electrical problems can range from a faulty thermostat to a blown fuse or a malfunctioning compressor clutch.

To troubleshoot electrical issues, check the wiring connections, fuses, and relays associated with your truck’s air conditioning system. Ensure that all connections are tight and secure, and replace any blown fuses or faulty components. If you are unfamiliar with electrical systems, it is advisable to seek professional assistance to avoid any further damage.

Compressor Failure

A compressor failure is a significant issue that can disrupt the entire functioning of your truck’s air conditioner. The compressor is responsible for pressurizing refrigerant and circulating it through the system. If the compressor fails, the cooling process comes to a halt.

Common signs of compressor failure include unusual noises, such as clanking or grinding sounds, and a complete lack of cool air. If you suspect a compressor failure, it is imperative to have it inspected and repaired by a qualified technician. Attempting to fix a compressor issue without proper knowledge and tools can lead to further damage.

Regular maintenance and prompt attention to these common issues can help ensure the longevity and efficient performance of your truck’s air conditioner. By taking the necessary steps to troubleshoot and address these problems, you can enjoy a comfortable and cool driving experience even during the hottest of days.

Credit: carolinacat.com

Steps To Troubleshoot Truck Air Conditioner Problems

Having a properly functioning air conditioner is essential for truck drivers, especially during long journeys or hot summer days. However, air conditioner issues can occur, causing discomfort and inconvenience on the road. Instead of spending valuable time and money at a repair shop, you can save time and troubleshoot the problems yourself. By following these simple steps, you can identify and possibly resolve common truck air conditioner problems.

Check Refrigerant Levels

One common cause of truck air conditioner issues is low refrigerant levels. Insufficient levels can result in inadequate cooling or a complete lack of cold air. Therefore, the first step in troubleshooting is to check the refrigerant levels. The process involves:

- Locate the refrigerant ports on your truck’s air conditioning system. Commonly, they are found on the high and low sides of the system.

- Attach a refrigerant pressure gauge to the low-side port. Refer to your truck’s manual for specific instructions on locating and using the ports.

- Start the engine and turn on the air conditioner to the maximum cooling setting.

- Read the gauge and compare the pressure with the recommended level specified in your truck’s manual.

- If the pressure is below the recommended level, you may need to add more refrigerant. However, do note that handling refrigerant requires expertise and specific tools. If you’re unsure or uncomfortable doing this yourself, it’s best to seek professional assistance.

Test Electrical Connections

Faulty electrical connections can also cause problems with your truck’s air conditioner. To ensure everything is working properly, follow these steps to test the electrical connections:

- Turn off the engine and disconnect the truck’s battery to prevent any accidental electrical shocks or short circuits.

- Locate the air conditioner’s electrical connections, including the fuse box and any wiring leading to the unit.

- Inspect the connections for any signs of damage, such as corrosion or loose wires.

- Tighten any loose connections and clean away any corrosion, using appropriate tools and cleaning agents.

- Replace any damaged fuses or wires, following your truck’s manual for guidance.

- Once you’ve completed these steps, reconnect the truck’s battery and start the engine to test if the air conditioner is now functioning properly.

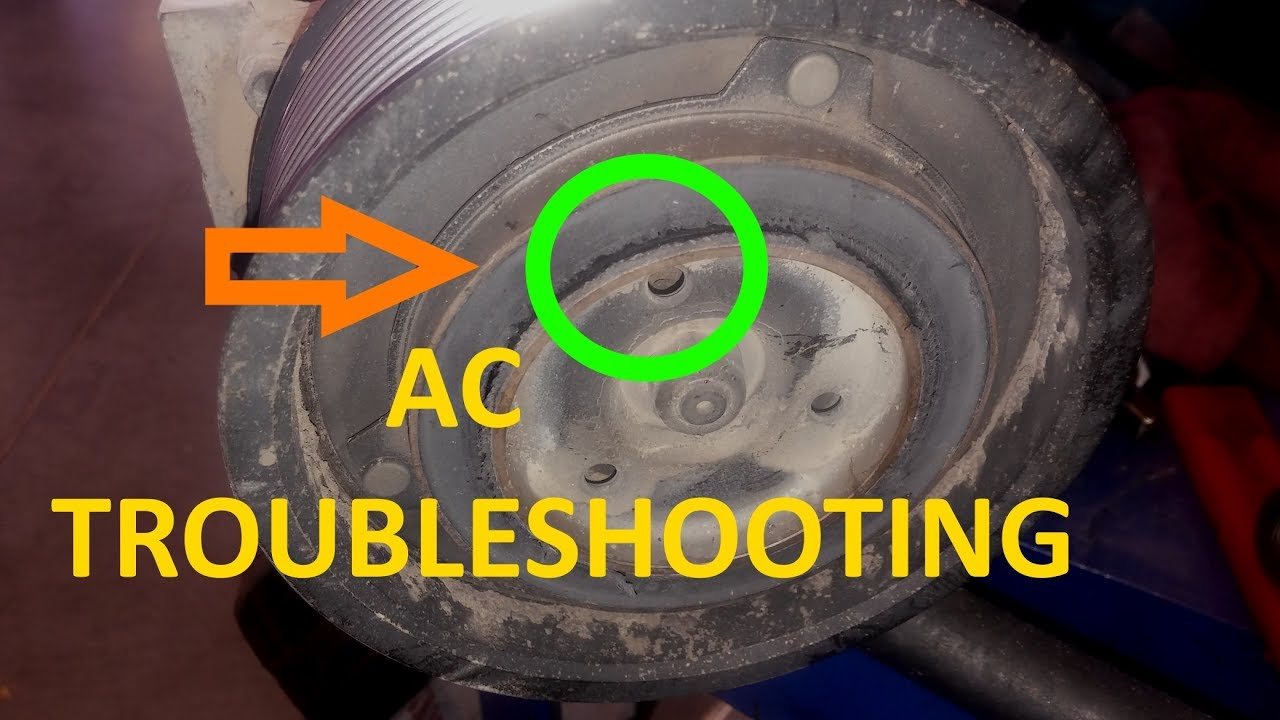

Inspect Compressor

The compressor is the heart of your truck’s air conditioning system, and if it’s not functioning correctly, it can cause cooling problems. To troubleshoot the compressor, follow these steps:

- Locate the compressor under the hood of your truck, typically near the belt system.

- Check the drive belt for any signs of wear, cracks, or damage. Replace the belt if necessary, as a worn-out belt can prevent the compressor from running smoothly.

- Inspect the compressor for any leaks, as refrigerant leaks can cause cooling inefficiency. Look for oil stains or wet spots around the compressor, indicating a leak.

- If you suspect a refrigerant leak, it’s best to consult a professional for repair, as handling refrigerant without proper knowledge can be hazardous.

- Lastly, ensure that the compressor clutch engages when you turn on the air conditioner. If the clutch does not engage, it may indicate a problem with the compressor or electrical connections, which will require further inspection or professional assistance.

By following these troubleshooting steps, you can potentially solve common truck air conditioner problems and enjoy a comfortable and cool ride on the road.

Preventive Maintenance For Truck Air Conditioners

Proper preventive maintenance is essential to keep your truck’s air conditioner running efficiently, especially during those scorching summer months. By following a regular maintenance routine, you can not only prevent breakdowns but also extend the lifespan of your air conditioner. Here are some important steps you can take to ensure your truck’s air conditioner is performing at its best.

Regular Cleaning And Maintenance

Regular cleaning and maintenance play a crucial role in maintaining the optimal performance of your truck’s air conditioner. Over time, dirt, dust, and debris can accumulate on the condenser coils, causing the system to work harder and potentially leading to reduced cooling capacity. To avoid this, it’s important to:

- Regularly clean the exterior of the air conditioner unit using a mild detergent and water solution.

- Clean or replace the air filter every three months or as recommended by the manufacturer to ensure proper airflow.

- Inspect the condenser coils for any debris or obstructions and clean them using a soft brush or compressed air.

- Check the drainage system for any clogs or blockages and clear them to prevent water leaks.

Proper Filter Replacement

The air filter in your truck’s air conditioner is responsible for trapping dust, pollen, and other airborne particles, preventing them from circulating through the system. Over time, these filters can become clogged, reducing airflow and straining the air conditioner. To ensure proper filter replacement:

- Refer to your truck’s manual or the manufacturer’s instructions to determine the type and size of filter required.

- Inspect the filter regularly for dirt and dust accumulation.

- If the filter appears dirty or clogged, replace it with a new one.

- Make sure to install the filter in the correct direction, following the arrows printed on the filter.

Keeping An Eye On Performance

Regularly monitoring the performance of your truck’s air conditioner can help you catch any potential issues early on and prevent major breakdowns. Keep an eye out for:

- Uneven cooling or loss of cooling capacity

- Strange noises or vibrations coming from the air conditioner

- Unusual odors when the system is running

- Increased energy consumption

- Water leaks or condensation buildup

If you notice any of these signs, it’s important to have your air conditioner inspected and repaired by a professional as soon as possible. Ignoring these issues can lead to more extensive and costly repairs down the line. By following these preventive maintenance steps, you can ensure your truck’s air conditioner remains in top-notch condition, keeping you cool and comfortable on the road.

Credit: www.facebook.com

Frequently Asked Questions On Truck Air Conditioner Troubleshooting

How Do I Troubleshoot A Truck Air Conditioner That Is Not Blowing Cold Air?

To troubleshoot a truck air conditioner that is not blowing cold air, check the refrigerant levels, inspect the compressor for damage, clean or replace the air filters, ensure proper airflow in the cabin, and examine the condenser for any obstructions.

Why Is My Truck Air Conditioner Not Turning On?

If your truck air conditioner is not turning on, check the fuse box for any blown fuses, ensure the thermostat is set to the correct temperature, inspect the wiring for any loose connections or damage, and make sure the engine is running.

Why Is My Truck Air Conditioner Making Strange Noises?

If your truck air conditioner is making strange noises, it could be due to a worn-out fan belt, a damaged compressor, loose components, or debris in the air vents. It is important to have it inspected and repaired by a professional to prevent further damage.

Conclusion

Troubleshooting your truck’s air conditioner doesn’t have to be a daunting task. By following these simple steps and being aware of common issues, you can save time and money. Regular maintenance and prompt repairs are key to ensuring a cool and comfortable ride.

Remember to consult a professional if you encounter complex problems. Stay cool on the road!