To troubleshoot the Lochinvar Copper-Fin 2, start by checking for error codes and ensuring proper gas supply. Inspect wiring and connections for faults.

The Lochinvar Copper-Fin 2 is a widely used water heater known for its efficiency and reliability. Despite its robust design, occasional issues can arise, requiring effective troubleshooting. Common problems include ignition failures, fluctuating water temperatures, and error codes on the display.

Addressing these issues promptly ensures optimal performance and longevity. Regular maintenance, such as checking gas supply and inspecting wiring, can prevent many common problems. Understanding the basics of troubleshooting the Lochinvar Copper-Fin 2 can save time and reduce the need for professional repairs. This guide aims to provide clear steps to identify and resolve common issues efficiently.

Common Issues

The Lochinvar Copper-Fin 2 is a reliable water heater, but it faces some common issues. Troubleshooting these can save time and money. Below are some frequent problems users encounter.

Ignition Problems

Ignition problems are common in the Lochinvar Copper-Fin 2. This issue often causes the heater to fail to start. Here are some potential causes and solutions:

- Gas Supply: Check if the gas supply is turned on. Make sure there are no leaks.

- Igniter: Inspect the igniter. Clean it if it’s dirty or replace it if it’s faulty.

- Wiring: Examine the wiring connections. Ensure they are secure and not damaged.

Temperature Fluctuations

Temperature fluctuations can be frustrating. They often make the water heater unreliable. Here are some possible reasons and fixes:

- Thermostat Settings: Verify the thermostat settings. Adjust them to the desired temperature.

- Sensors: Check the temperature sensors. Clean them if they are dirty or replace them if faulty.

- Water Flow: Ensure there is proper water flow. Low flow can cause temperature changes.

Understanding and addressing these common issues can enhance the performance of your Lochinvar Copper-Fin 2. Regular maintenance can also help prevent these problems.

Credit: www.youtube.com

Diagnostic Tools

Diagnostic tools are crucial for troubleshooting the Lochinvar Copper-Fin 2. They help identify and solve issues quickly. Having the right tools ensures your boiler runs smoothly.

Essential Tools

You need several essential tools for effective troubleshooting. These tools help in diagnosing and fixing common problems.

- Multimeter: Measures voltage, current, and resistance.

- Manometer: Checks gas and water pressure.

- Thermometer: Monitors temperature levels.

- Combustion Analyzer: Examines flue gases.

These tools are vital for accurate diagnostics. They help ensure your boiler operates efficiently.

Using Diagnostic Software

Diagnostic software can simplify troubleshooting. It provides detailed insights into the boiler’s performance.

Here are the steps to use diagnostic software:

- Connect the diagnostic tool to the boiler.

- Open the software on your computer or device.

- Run a full system scan.

- Analyze the error codes and data.

- Follow the software’s recommendations to fix issues.

Using software helps pinpoint specific problems. It can save time and effort in troubleshooting.

| Tool | Function |

|---|---|

| Multimeter | Measures electrical values |

| Manometer | Checks pressure levels |

| Thermometer | Monitors temperature |

| Combustion Analyzer | Examines flue gases |

Keep these tools handy for effective troubleshooting. They ensure your Lochinvar Copper-Fin 2 operates without issues.

Step-by-step Troubleshooting

Understanding how to troubleshoot your Lochinvar Copper-Fin 2 boiler can save you both time and money. This step-by-step guide will help you identify and resolve common issues. Follow these instructions to ensure your boiler operates efficiently.

Initial Checks

Begin with basic initial checks to rule out simple problems. Ensure the unit is powered on. Verify that the thermostat is set correctly. Confirm the gas supply is active. Examine the boiler’s display for error codes.

- Check power supply.

- Set thermostat correctly.

- Verify gas supply.

- Inspect display for error codes.

Detailed Inspection

If initial checks don’t solve the issue, perform a detailed inspection. First, assess the water pressure. Low pressure can cause malfunctions.

| Component | Inspection |

|---|---|

| Water Pressure | Ensure pressure gauge reads 1-2 bars. |

| Burner | Check for any blockages. |

| Heat Exchanger | Inspect for signs of corrosion or leaks. |

| Ventilation | Ensure vents are clear and unobstructed. |

Use a multimeter to check electrical connections. Loose or damaged wires can cause problems.

- Turn off the power supply.

- Inspect wires and connectors.

- Tighten any loose connections.

- Replace damaged wires.

Pay special attention to the heat exchanger. Look for signs of wear and tear.

Keep your boiler well-maintained to avoid frequent issues. Regular inspections ensure longevity and efficiency.

Credit: www.lochinvar.com

Repair Solutions

Troubleshooting the Lochinvar Copper-Fin 2 can be challenging. This section covers essential repair solutions. Follow these steps to fix common issues efficiently.

Replacing Faulty Parts

Sometimes, parts in your Lochinvar Copper-Fin 2 may fail. Replacing these parts is crucial for optimal performance. Here are some common parts that may need replacement:

- Ignition Control: If the boiler doesn’t ignite, check the ignition control.

- Thermostat: A faulty thermostat can cause temperature issues.

- Pressure Switch: Replace if you notice pressure-related problems.

Follow these steps to replace a faulty part:

- Turn off the power to the boiler.

- Remove the access panel.

- Identify the faulty part.

- Disconnect the wires and remove the part.

- Install the new part and reconnect the wires.

- Replace the access panel and turn on the power.

Adjusting Settings

Sometimes, simply adjusting the settings can resolve issues. Here are some settings to check:

- Temperature Settings: Ensure the thermostat is set correctly.

- Pressure Settings: Check and adjust the pressure settings.

- Ignition Timing: Adjust the ignition timing if the boiler won’t start.

Follow these steps to adjust the settings:

- Turn off the power to the boiler.

- Access the control panel.

- Use the manual to locate the settings.

- Adjust the settings as needed.

- Replace the control panel cover and turn on the power.

By following these repair solutions, you can keep your Lochinvar Copper-Fin 2 running smoothly.

Preventative Measures

Preventative measures are crucial for maintaining the Lochinvar Copper-Fin 2 boiler. Regular maintenance helps prevent unexpected breakdowns and extends the boiler’s lifespan. By following these steps, you can ensure your boiler runs efficiently and safely.

Regular Maintenance Tips

Maintaining your Lochinvar Copper-Fin 2 boiler involves consistent checks and services. Regular maintenance can prevent costly repairs and ensure your boiler operates efficiently.

- Check the Water Levels: Ensure water levels are within the recommended range.

- Inspect for Leaks: Regularly check for any visible leaks.

- Clean the Burners: Remove any dirt or debris from the burners.

- Test the Safety Controls: Verify that all safety controls are working properly.

Common Preventative Practices

Implementing common preventative practices can help maintain the Lochinvar Copper-Fin 2 boiler. These practices can save time and money in the long run.

- Annual Inspections: Schedule a yearly inspection by a certified technician.

- Regular Filter Changes: Replace filters every three to six months.

- Monitor Pressure Levels: Keep an eye on pressure levels to avoid overheating.

- Flue Gas Analysis: Conduct a flue gas analysis to ensure proper combustion.

Maintenance Schedule Table

| Task | Frequency |

|---|---|

| Check Water Levels | Weekly |

| Inspect for Leaks | Monthly |

| Clean Burners | Every 6 months |

| Annual Inspection | Yearly |

Professional Help

When troubleshooting your Lochinvar Copper-Fin 2, some issues need professional help. Understanding when to call a technician can save time and avoid costly mistakes. Here’s a guide to help you decide.

When To Call A Technician

If your boiler shows error codes, it’s time to call a technician. Some error codes indicate serious issues that need professional attention.

- Error Code E01: Ignition failure

- Error Code E02: Flame failure

- Error Code E03: High limit fault

If you hear strange noises from the boiler, this is another sign. Banging or clanking sounds often mean internal parts are malfunctioning.

If your boiler leaks, it’s important to get help immediately. Water leaks can cause significant damage to your property.

Finding Reliable Service Providers

Look for technicians who are certified in Lochinvar products. Certification ensures they have the necessary training and experience.

Check online reviews to find reliable service providers. Customer feedback can give insights into their reliability and quality of work.

| Company | Rating | Contact |

|---|---|---|

| ABC Heating | 4.8/5 | 123-456-7890 |

| XYZ Plumbing | 4.6/5 | 987-654-3210 |

Ask friends or neighbors for recommendations. Personal referrals are often the most trustworthy.

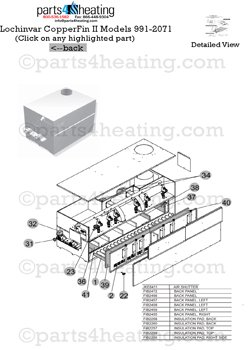

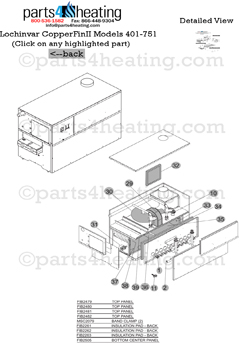

Credit: www.parts4heating.com

Frequently Asked Questions

How Do I Reset My Lochinvar Copper-fin 2?

To reset your Lochinvar Copper-Fin 2, turn off the power. Wait for 10 seconds. Then, turn the power back on. This should reset the system.

Why Is My Lochinvar Copper-fin 2 Not Heating?

If your Lochinvar Copper-Fin 2 isn’t heating, check the gas supply. Ensure the thermostat is set correctly. Inspect for any error codes on the display.

What Does A Fault Code On Lochinvar Mean?

A fault code on your Lochinvar indicates a specific problem. Refer to the user manual to identify the exact issue. Address the problem as per the manual’s instructions.

How Often Should I Service My Lochinvar Boiler?

Service your Lochinvar boiler annually. Regular maintenance ensures optimal performance and extends the lifespan of the unit. Professional servicing is recommended.

Conclusion

Troubleshooting your Lochinvar Copper-Fin 2 can be straightforward with the right guidance. Follow the steps outlined for best results. Regular maintenance ensures longevity and efficient performance. Stay proactive to avoid unexpected issues. For complex problems, consult a professional. Keep your system running smoothly with these simple tips.