Is your furnace not working correctly? It might be due to a pressure switch issue.

Furnace pressure switch troubleshooting can help you identify and fix common problems, ensuring your home stays warm and comfortable. A furnace pressure switch is a safety device. It ensures the burner operates correctly. When it malfunctions, your furnace might shut down.

This can be frustrating, especially during cold months. Understanding how to troubleshoot this switch can save you time and money. In this guide, we will explore common pressure switch problems, their causes, and how to fix them. By learning these basics, you can maintain your furnace and keep your home cozy all winter long.

Introduction To Furnace Pressure Switch

Understanding furnace pressure switch troubleshooting is essential for maintaining your furnace’s efficiency. This switch monitors air pressure to ensure safe operation. Identifying issues early helps prevent major breakdowns.

A furnace pressure switch plays a crucial role in your heating system. This small yet vital component ensures your furnace operates safely and efficiently. Understanding its function and troubleshooting it can save you from costly repairs.What Is A Pressure Switch?

A pressure switch is a safety device in your furnace. It monitors the pressure in the furnace’s combustion chamber. If the pressure is too high or too low, it stops the furnace from running. This prevents dangerous situations like gas leaks or explosions.Importance In Furnace Operation

The pressure switch ensures your furnace runs smoothly. It detects issues before they become serious problems. A faulty pressure switch can lead to furnace shutdowns. Regularly checking the pressure switch can help maintain your furnace. It ensures your home stays warm and safe during cold months. “`

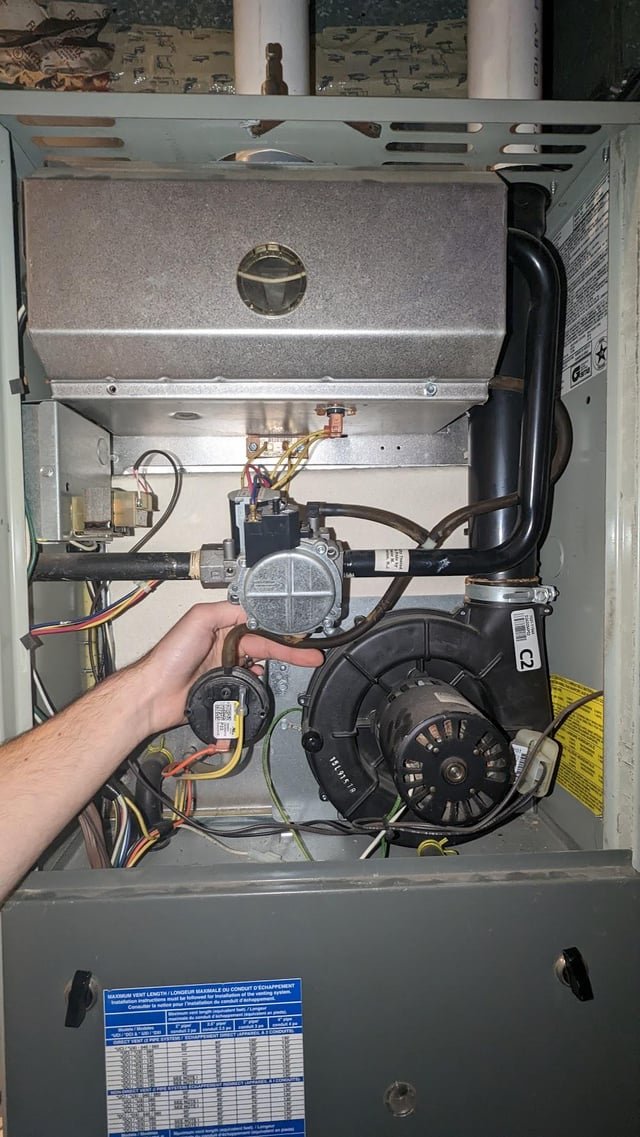

Credit: foxfamilyhvac.com

Common Pressure Switch Issues

Troubleshooting a furnace pressure switch can be a daunting task, especially when you encounter common issues. Understanding these issues can help you diagnose and fix problems quickly. Here, we’ll explore some of the most frequent pressure switch issues and how you can address them.

Blockages And Obstructions

Blockages in the furnace’s venting system are a common cause of pressure switch problems. These blockages can be caused by debris, nests, or even ice during the winter. If the vent is blocked, the pressure switch won’t detect the correct airflow, causing the furnace to shut down.

Check the vent pipes for any signs of obstructions. Remove any debris or blockages you find. Be cautious when dealing with nests or ice, as these can sometimes be tricky to clear.

Regular maintenance can help prevent blockages. Make it a habit to inspect your venting system periodically. This proactive approach can save you from unexpected furnace shutdowns.

Electrical Connection Problems

Another common issue with furnace pressure switches involves electrical connections. Loose or faulty connections can prevent the pressure switch from functioning correctly. This can lead to intermittent operation or complete failure of the furnace.

Inspect the wiring connected to the pressure switch. Ensure all connections are secure and free from corrosion. If you notice any damaged wires, replace them promptly.

Using a multimeter, you can test the electrical continuity of the pressure switch. This tool can help you determine if the switch is receiving power and sending the correct signals. If the switch fails the test, it may need replacement.

Have you ever faced these common pressure switch issues? How did you tackle them? Share your experiences in the comments below!

Tools Needed For Troubleshooting

A multimeter, screwdriver, and manometer are essential for furnace pressure switch troubleshooting. These tools help identify issues efficiently. Accurate readings ensure proper diagnosis and repair.

Troubleshooting your furnace’s pressure switch can seem daunting. However, having the right tools can make the process a lot easier. In this section, we’ll discuss the essential tools you need for effective troubleshooting. ###Basic Tools

When you start troubleshooting, having a set of basic tools is crucial. Screwdrivers: A set of both flathead and Phillips screwdrivers will help you remove the furnace cover and access the pressure switch. Multimeter: This handy device allows you to measure voltage, current, and resistance. It’s essential for checking the electrical connections and ensuring the pressure switch is working properly. Flashlight: Sometimes, furnace components are located in poorly lit areas. A flashlight ensures you can see everything clearly. ###Specialized Equipment

While basic tools are indispensable, some specialized equipment can make troubleshooting more efficient and accurate. Manometer: This device measures the pressure inside your furnace. By comparing the readings to the manufacturer’s specifications, you can determine if the pressure switch is working correctly. Tubing cutter: If you need to replace any tubing connected to the pressure switch, a tubing cutter ensures clean and precise cuts. Hand-held vacuum pump: This can help you test the pressure switch by simulating the pressure conditions in the furnace. Having the right tools on hand not only makes troubleshooting easier but also more effective. Did you ever find yourself halfway through a project and realize you’re missing a tool? It’s frustrating, right? Preparing ahead can save you time and stress. So, gather these tools before you start your furnace troubleshooting journey. What’s the one tool you always forget but wish you had on hand?Safety Precautions

Ensure your furnace operates safely by checking the pressure switch. Regular inspection prevents malfunctions and potential hazards. Familiarize yourself with troubleshooting steps to maintain a safe home environment.

### Safety Precautions When troubleshooting your furnace’s pressure switch, safety should be your top priority. Working with heating systems can be risky, but following some basic precautions can make a big difference. ####Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE). This includes gloves, safety glasses, and long sleeves. The goal is to protect yourself from burns, electrical shocks, and other hazards. It’s not just about being safe but feeling safe too. Would you want to risk injury for the sake of a quick fix? Definitely not. ####Shutting Down The Furnace

Before you start any troubleshooting, shut down the furnace completely. Turn off the power at the main switch or breaker. This step is crucial to prevent electrical shocks. Even if you think the problem is minor, never skip this step. Imagine dealing with a live wire; it’s not a situation you’d want to be in. Better safe than sorry. Engaging directly with your furnace without proper precautions can lead to serious injury. Always prioritize your safety.Initial Inspection

Begin furnace pressure switch troubleshooting with an initial inspection. Check for any visible damage or loose connections. Ensure the switch is clean and properly aligned.

When your furnace isn’t working properly, it can be frustrating and uncomfortable. One common issue is a malfunctioning pressure switch. An initial inspection can help you identify the problem and determine the next steps for repair.Visual Inspection

Start by visually inspecting your furnace. Look for any loose wires or connections. Check if the pressure switch’s tubing is intact and connected properly. Ensure there is no visible damage or obstructions around the switch and its components.Listening For Unusual Sounds

Turn on your furnace and listen closely. Can you hear any unusual sounds? A clicking noise can indicate the pressure switch is trying to operate but failing. If there’s a continuous humming or buzzing sound, it might be a sign of an electrical issue. This could affect the pressure switch’s functionality. By beginning with these simple inspections, you can often pinpoint the issue early. Have you noticed any of these signs in your furnace? Taking action now can prevent bigger problems later.

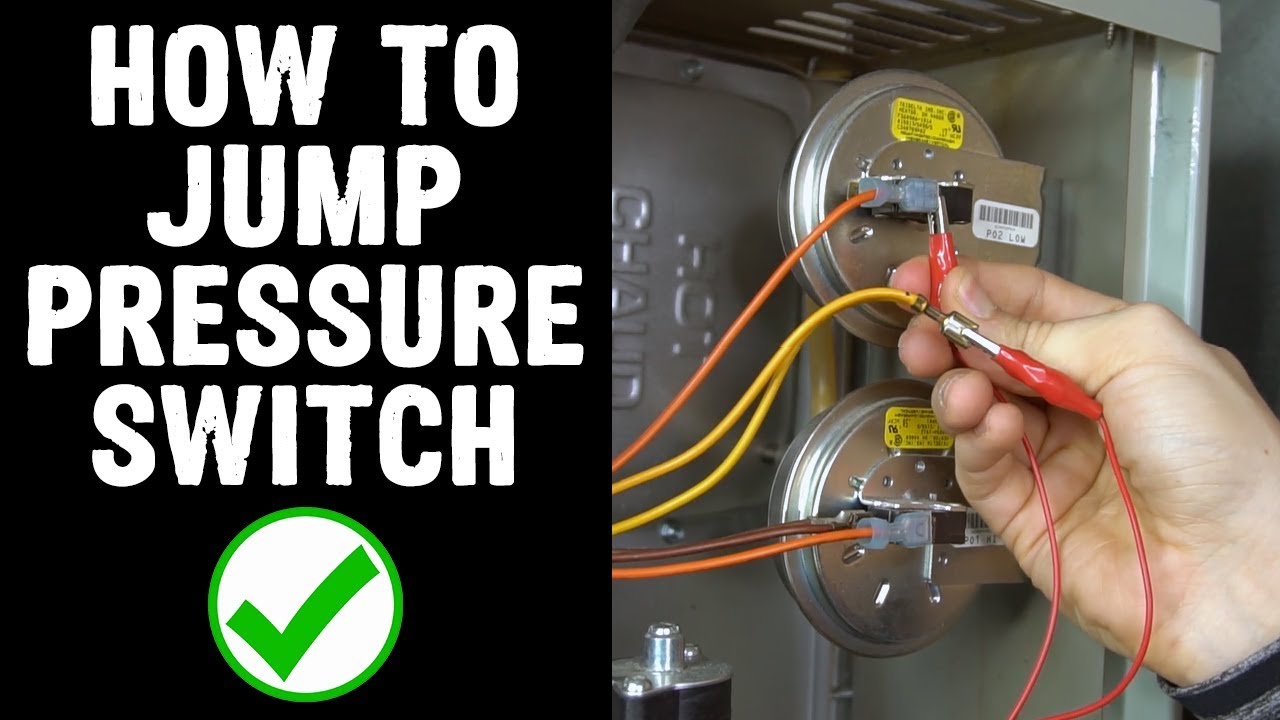

Credit: m.youtube.com

Testing The Pressure Switch

Testing the furnace pressure switch is essential for ensuring proper operation. A malfunctioning pressure switch can cause the furnace to shut down. This section will guide you through using a multimeter and checking for continuity.

Using A Multimeter

A multimeter is a useful tool for testing electrical components. To test the pressure switch, first, set your multimeter to measure voltage. Next, locate the terminals on the pressure switch. Touch the multimeter probes to the terminals. Observe the reading on the multimeter. The reading should match the voltage specified in the furnace manual.

If the reading is incorrect, the pressure switch may be faulty. It’s important to ensure your multimeter is set correctly. Double-check the settings and try again. If the reading is still off, replacement may be necessary.

Checking For Continuity

Checking for continuity helps determine if the pressure switch is functioning. Set your multimeter to the continuity setting. Disconnect the wires from the pressure switch. Touch the probes to the pressure switch terminals.

If the multimeter beeps, the switch has continuity. This means the switch is allowing electrical flow. If there is no beep, the switch lacks continuity. This indicates a problem with the pressure switch. Continuity issues often require a replacement.

Cleaning And Maintenance

Regular cleaning and maintenance of your furnace pressure switch ensures optimal performance. Neglecting this can lead to malfunctions and decreased efficiency. Learn how to clean and maintain your furnace pressure switch below.

Cleaning The Switch

First, turn off the power to the furnace. Locate the pressure switch, usually near the draft inducer motor. Gently remove the switch using a screwdriver. Inspect the switch for dirt, dust, or debris.

Use a soft brush or cloth to clean the switch. Be careful not to damage any components. If needed, use compressed air to blow away stubborn dirt. Reattach the switch securely once it’s clean.

Preventative Measures

Regularly check the pressure switch for signs of wear or damage. Replace it if necessary. Keep the furnace area clean to prevent dust buildup. Schedule annual furnace maintenance with a professional. This helps identify potential issues early. Keep the vent system clear to ensure proper airflow.

These steps help maintain your furnace pressure switch. A clean switch means a more efficient furnace. This can save you money on energy bills. Proper maintenance extends the life of your furnace.

Credit: m.youtube.com

When To Replace The Pressure Switch

A pressure switch replacement is needed if your furnace frequently cycles on and off. Also, replace it when the furnace fails to start.

### When to Replace the Pressure Switch Replacing the pressure switch in your furnace is crucial for maintaining its efficiency and safety. If your furnace is acting up, the pressure switch might be to blame. But how do you know when it’s time for a replacement? ####Signs Of A Faulty Switch

Is your furnace failing to start? This could be a red flag. A faulty pressure switch often prevents the furnace from igniting. Another sign is hearing the blower fan running, but there’s no heat. This happens because the pressure switch isn’t signaling the furnace to begin the heating cycle. Have you noticed any error codes on your furnace? Modern furnaces often display codes that indicate a malfunctioning pressure switch. Refer to your manual for specifics. ####Choosing A Replacement

Selecting the right replacement switch is vital. Make sure the new switch matches the specifications of your current one. This ensures compatibility and proper functioning. Always check the pressure rating. Incorrect ratings can lead to safety hazards or inefficient heating. Consult your furnace manual for these details. You can purchase replacements from HVAC suppliers or online stores. Look for reputable brands and read reviews to ensure reliability. Consider having a professional install it. While it might seem straightforward, incorrect installation can cause further issues. Replacing a pressure switch isn’t just about fixing a problem; it’s about ensuring your furnace runs safely and efficiently. Pay attention to the signs and choose the right replacement to keep your home warm and safe.Frequently Asked Questions

How Do I Know If My Furnace Pressure Switch Is Bad?

Check for furnace error codes, unusual noises, or frequent cycling. Test the switch with a multimeter.

How Do I Know If My Pressure Switch Is Bad?

Check for inconsistent water pressure, the pump not turning on/off, or unusual noises. Use a multimeter to test continuity.

What Causes A Furnace Pressure Switch To Trip?

A furnace pressure switch can trip due to blocked vents, dirty filters, or malfunctioning inducer motors. Ensure proper airflow and regular maintenance to prevent issues.

Can You Reset A Pressure Switch On A Furnace?

Yes, you can reset a pressure switch on a furnace. Turn off the power, locate the switch, and press the reset button.

Conclusion

Troubleshooting your furnace pressure switch can seem challenging. But it’s manageable. Follow the steps outlined in this guide. Ensure safety first. Check for blockages and proper airflow. Regular maintenance prevents many issues. Replace faulty switches if needed. A well-functioning furnace keeps your home comfortable.

Always consult a professional for complex issues. Happy troubleshooting!