For Nordson glue machine troubleshooting, check the power supply and ensure proper settings. Inspect for clogs or damage in the adhesive lines.

Nordson glue machines are vital for efficient adhesive applications in manufacturing. They enhance productivity and ensure high-quality bonding. However, like any machinery, they can encounter issues that disrupt operations. Understanding common problems and their solutions can minimize downtime. Troubleshooting these machines requires a systematic approach to identify and resolve issues.

Regular maintenance and prompt attention to warning signs can prolong the equipment’s lifespan. This guide aims to provide practical troubleshooting tips, helping you keep your Nordson glue machine running smoothly and efficiently. Stay informed to optimize your adhesive processes and maintain production quality.

Credit: www.nordson.com

Introduction To Nordson Glue Machines

Nordson glue machines are vital for many industries. They provide efficient adhesive solutions. These machines apply glue consistently and accurately. This ensures strong bonds in various materials.

Importance In Industrial Applications

Nordson glue machines play a key role in industrial settings. Their importance includes:

- Efficiency: Fast application saves time.

- Precision: Accurate glue placement minimizes waste.

- Versatility: Works with different materials like paper, wood, and plastics.

- Cost-Effective: Reduces glue usage and labor costs.

These machines are essential for production lines. They enhance product quality and consistency. Many manufacturers rely on Nordson technology for their adhesive needs.

Common Models And Their Uses

| Model | Application | Key Features |

|---|---|---|

| Nordson ProBlue | Packaging | Fast heating and easy maintenance |

| Nordson H-2000 | Woodworking | High precision and low glue usage |

| Nordson VersaBlue | Automotive | Durable construction for heavy use |

Each model serves specific industrial needs. Choosing the right machine ensures optimal performance. Understanding these models helps in making informed decisions.

Initial Setup Checks

Setting up your Nordson glue machine correctly is crucial. Initial setup checks ensure smooth operation. Follow these steps to avoid common issues.

Ensuring Proper Installation

Proper installation is vital for your glue machine’s performance. Follow these steps:

- Place the machine on a stable surface.

- Ensure all components are securely attached.

- Check for any visible damage.

- Verify that the glue feed system is connected properly.

Use the following checklist to confirm proper installation:

| Check | Status |

|---|---|

| Stable surface | ✔️ |

| All components attached | ✔️ |

| No visible damage | ✔️ |

| Glue feed connection | ✔️ |

Verifying Power Supply And Settings

A reliable power supply is essential. Check these settings:

- Confirm the voltage matches the machine requirements.

- Ensure the power cord is securely plugged in.

- Check the power switch is in the ON position.

Follow these steps to verify settings:

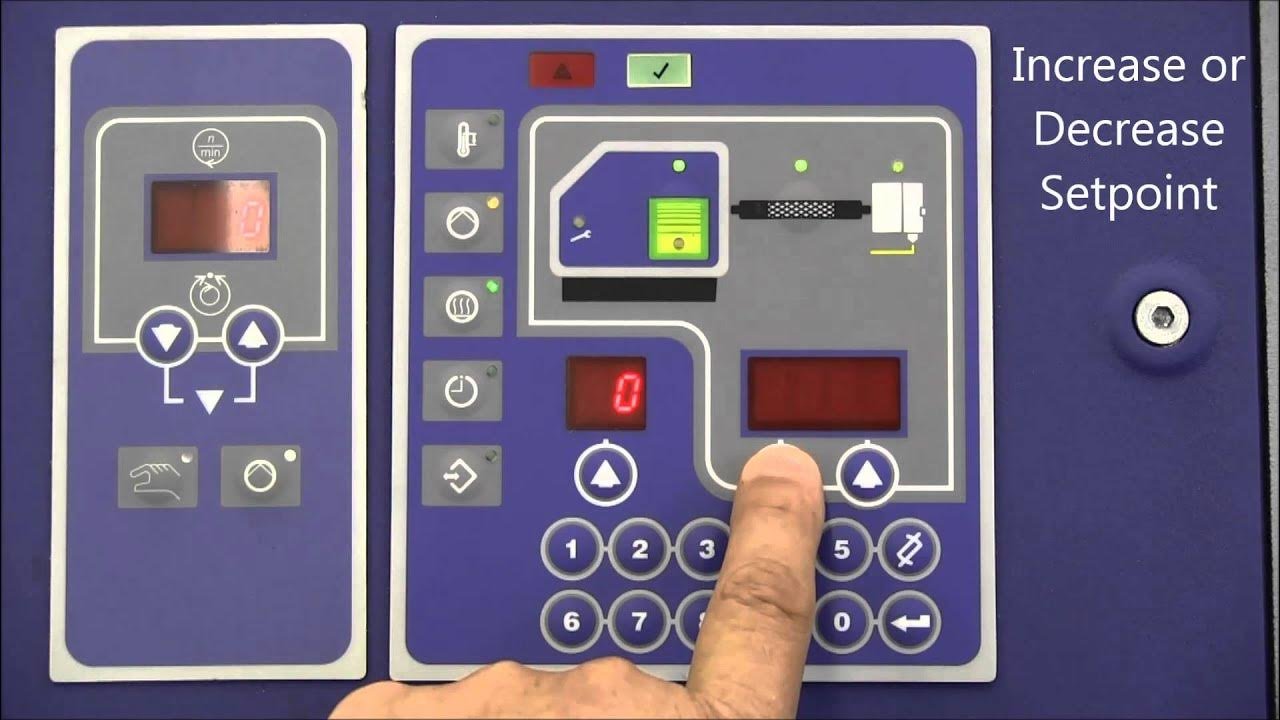

- Locate the power settings on the control panel.

- Adjust settings according to the manual.

- Test the machine with a small batch of glue.

By following these initial setup checks, you minimize troubleshooting later.

Common Glue Machine Issues

Nordson glue machines are reliable but can face issues. Understanding these common problems helps you troubleshoot effectively. Here are the main issues you might encounter.

Adhesive Not Heating

One frequent problem is the adhesive not heating. This issue can disrupt production and lead to wasted materials. Here are some common causes:

- Thermostat Malfunction: A faulty thermostat may not regulate temperature.

- Power Supply Issues: Check if the machine is receiving power.

- Heating Element Failure: A broken heating element won’t heat the adhesive.

To troubleshoot:

- Inspect the power source for any disruptions.

- Test the thermostat with a multimeter.

- Replace the heating element if necessary.

Inconsistent Glue Flow

Inconsistent glue flow can ruin your project. It leads to uneven application and poor bonding. Here are some causes for this issue:

- Clogged Nozzle: Debris can block the nozzle, causing flow issues.

- Pump Problems: A malfunctioning pump may not deliver consistent pressure.

- Viscosity Changes: Changes in adhesive thickness can affect flow.

To fix inconsistent glue flow:

- Clean the nozzle to remove any blockages.

- Check the pump for any operational problems.

- Ensure the adhesive is at the correct viscosity.

Regular maintenance can prevent many of these issues.

Credit: pdf.directindustry.com

Quick-fix Strategies

Nordson glue machines can face issues. Quick-fix strategies help you resolve common problems. These strategies save time and keep production running smoothly.

Clearing Nozzle Blockages

Nozzle blockages are common in glue machines. They can disrupt the flow of adhesive. Follow these steps to clear blockages:

- Turn off the machine.

- Remove the nozzle carefully.

- Inspect for any glue residue or debris.

- Use a soft brush to clean.

- Rinse the nozzle with warm water.

- Reattach the nozzle securely.

- Turn the machine back on.

Regular cleaning helps prevent blockages. Schedule weekly maintenance for best results.

Adjusting Temperature Controls

Temperature control is crucial for glue application. Incorrect settings can lead to poor adhesion. Follow these steps to adjust:

- Check the current temperature setting.

- Compare with the recommended temperature for your glue type.

- Use the control panel to adjust the temperature.

- Wait for the machine to reach the new setting.

- Test the glue application.

Maintain a consistent temperature. This ensures optimal performance and reduces glue waste.

Preventative Maintenance Tips

Proper maintenance of your Nordson glue machine can prevent issues. Regular care keeps your machine running smoothly. Follow these tips for effective maintenance.

Regular Cleaning Routines

Cleaning is essential for the longevity of your machine. Dust, debris, and glue buildup can cause problems. Establish a routine for cleaning the following parts:

- Nozzles: Clear any blockages.

- Filters: Replace or clean as needed.

- Reservoirs: Keep them free of residue.

- External Surfaces: Wipe down to remove dirt.

Use the following cleaning schedule:

| Frequency | Task |

|---|---|

| Daily | Wipe external surfaces |

| Weekly | Clean nozzles and filters |

| Monthly | Inspect and clean reservoirs |

Scheduled Inspection Plans

Regular inspections help spot potential issues early. Create a checklist to ensure all areas are covered:

- Check for leaks in glue lines.

- Inspect electrical connections.

- Test the pressure settings.

- Review the operation of the control panel.

Schedule inspections based on usage:

- Low Usage: Every 6 months

- Moderate Usage: Every 3 months

- Heavy Usage: Monthly

Document all inspections. This practice helps track issues over time.

Advanced Troubleshooting Techniques

Advanced troubleshooting techniques help you fix Nordson Glue Machines quickly. These methods focus on two main areas: electrical faults and pressure issues. Understanding these areas can save time and reduce downtime.

Diagnosing Electrical Faults

Electrical faults can cause significant problems in glue machines. Follow these steps to diagnose issues:

- Check the power supply. Ensure it is stable and correct.

- Inspect the wiring. Look for frayed or damaged wires.

- Test the fuses. Replace any blown fuses immediately.

- Use a multimeter. Measure voltage at various points.

- Examine control boards. Look for burnt components or loose connections.

Common electrical faults include:

- Power interruptions

- Faulty sensors

- Overheating components

Addressing these issues promptly helps maintain machine performance.

Resolving Pressure Problems

Pressure issues can affect glue application. Here are steps to resolve them:

- Check the pressure gauge. Ensure it reads correctly.

- Inspect hoses for blockages or leaks.

- Verify the pump operation. Ensure it runs smoothly.

- Adjust the pressure settings. Use the manufacturer’s guidelines.

Common pressure problems include:

| Problem | Possible Cause | Solution |

|---|---|---|

| Low Pressure | Blocked filters | Clean or replace filters |

| Inconsistent Pressure | Faulty pump | Repair or replace the pump |

| High Pressure | Incorrect settings | Adjust settings to recommended levels |

Timely resolution of pressure issues ensures optimal glue application.

When To Seek Professional Help

Maintaining a Nordson glue machine is crucial for optimal performance. Some problems are easy to fix. Others require expert help. Knowing when to seek professional assistance saves time and prevents further damage.

Identifying Complex Issues

Some issues with your Nordson glue machine may be complex. Look for these signs:

- Frequent malfunctions: If problems occur often, it’s time to act.

- Unusual noises: Grinding or popping sounds indicate internal issues.

- Inconsistent glue application: Variations in glue flow can signal serious problems.

- Overheating: Excessive heat may damage components.

Document these issues. This information helps technicians diagnose the problem quickly. Don’t ignore small signs; they might lead to bigger issues.

Contacting Nordson Support

Contact Nordson Support when you notice complex issues. Follow these steps:

- Gather information: Note the model number and specific problems.

- Check the warranty: Ensure your machine is still covered.

- Call or email: Use the official Nordson contact methods.

- Prepare for questions: Be ready to explain the symptoms clearly.

Professional support can save time and money. Trained technicians have the right tools and experience. Avoid DIY fixes for complex issues.

Credit: www.youtube.com

Enhancing Machine Longevity

Maintaining your Nordson glue machine ensures it runs efficiently. Regular care extends its lifespan. Simple practices help avoid costly repairs.

Upgrade Options

Investing in upgrades can boost performance. Here are some options:

- New Nozzles: Improve glue application precision.

- Advanced Controllers: Enhance temperature and pressure control.

- Monitoring Systems: Track machine performance in real-time.

Consider upgrading components based on machine usage. This proactive approach leads to better performance.

Training For Operators

Well-trained operators can significantly impact machine longevity. Ensure they know:

- Machine Setup: Proper setup prevents malfunctions.

- Daily Maintenance: Regular checks keep the machine running smoothly.

- Problem-Solving Skills: Quick fixes reduce downtime.

Schedule regular training sessions. This investment pays off in the long run.

Troubleshooting Case Studies

Troubleshooting Nordson Glue Machines can be challenging. Real-world examples help uncover solutions. Understanding past issues leads to better practices.

Real-world Examples

Here are some common issues faced by users:

| Issue | Description | Resolution |

|---|---|---|

| Glue Clogging | Glue builds up and blocks the nozzle. | Clean the nozzle regularly. |

| Inconsistent Adhesion | Glue does not stick properly. | Check glue temperature settings. |

| Air Leaks | Air bubbles create uneven application. | Inspect all hoses and connections. |

Lessons Learned From Past Issues

- Regular Maintenance is key to preventing problems.

- Keep spare parts handy for quick fixes.

- Training staff improves troubleshooting skills.

- Identify the issue promptly.

- Refer to the user manual for guidance.

- Document each issue for future reference.

These case studies highlight the importance of effective troubleshooting. Users can reduce downtime and improve efficiency.

Frequently Asked Questions

What Are Common Issues With Nordson Glue Machines?

Common issues include improper adhesive flow, nozzle blockages, and electrical failures. Regular maintenance can prevent many of these problems. Check for clogs in the adhesive line and ensure all components are properly connected. If issues persist, consult the user manual for troubleshooting steps.

How Can I Fix A Clogged Glue Nozzle?

To fix a clogged glue nozzle, first, remove the nozzle from the machine. Clean it using a suitable solvent or adhesive cleaner. A soft brush may help dislodge stubborn residue. Reinstall the nozzle and test the machine to ensure proper adhesive flow.

Regular cleaning prevents future clogs.

Why Is My Nordson Glue Machine Leaking?

Leaking can occur due to worn seals or loose connections. Inspect all fittings and hoses for damage or wear. Tighten any loose components and replace worn seals immediately. Regular inspections can help catch these issues before they lead to significant leaks and downtime.

How Do I Reset My Nordson Glue Machine?

To reset your Nordson glue machine, locate the reset button on the control panel. Press and hold the button until the machine powers off. Wait a few seconds, then turn the machine back on. This process can resolve minor error codes and restore normal operation.

Conclusion

Troubleshooting your Nordson glue machine can save time and reduce frustration. Regular maintenance and prompt attention to issues ensure optimal performance. Always refer to your user manual for specific guidance. By staying proactive, you can maintain efficiency and extend the lifespan of your equipment.

Keep your operations running smoothly with these tips.